Case Study: The Importance of Lean Supervisor Training

A small manufacturing plant needed assistance with their management team. Supervisor checklists, day-to-day tasks, and production planning were tasks not being consistently completed and operational efficiency was being impacted. The supervisors were constantly reacting to problems instead of proactively planning ways to prevent them. The owner, ahead of a week-long trip, asked Prosit to train the supervisors and help them resolve these issues.

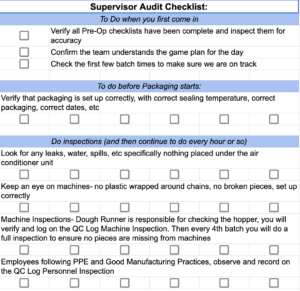

Prosit’s consultants worked together on a tandem process. Over a five-day period, the consultants walked the flow with supervisors and showed them how to anticipate and prevent problems. The supervisors were not clear on how their checklists were to be utilized so Prosit helped them fill out the 5S, Safety, PPE, and PTA checklists accurately. Prosit also trained the supervisors on batch size reduction, work distribution, and proper 5S techniques moving forward.

The five-day, on the job training, allowed the supervisors to fully understand the expectations and responsibilities of their daily jobs. They were able to effectively create an attainable production plan for the day, keep the operators working at their stations, and accurately fill out the checklists the owner had provided. These work documents portrayed accurate work content for future planning – and made the operations not only run more efficiently, but reduce the stress of the team.

Please contact Prosit to see how they can assist your company.